PVC

PVC

At Omni Manufacturing, we offer fluidized bed PVC coating of small- to mid-sized automotive components. We are capable of applying various colors of premium PVC coatings, where we can achieve a thickness of .1mm to .4mm. Contact us today to discuss any PVC coating needs you may have.

With the equipment Omni uses, we are capable of high-volume production using four automated thru-put coaters, all of which utilize the best-suited heat source for your individual project; be that infrared, fuel gas or induction heat source. Our fixture racking and tooling is engineered, designed and built in house to maximize efficiencies.

Here is a snapshot of a typical process at Omni Manufacturing:

- Parts are loaded to part-specific fixtures that are designed to maximize concentration

- They are then cycled to one or multiple heat stations per part requirements

- Next they are brought to powder melt/flow temperature and dipped into fluidized powder bed for predetermined time to achieve specified coating thickness (successive cycles)

- Parts then advance to multiple cool down stations

- When cool, the parts are unloaded and inspected to ISO 9001-2008 quality standards and packed for shipment

Our Capabilities

Stamping

Omni’s production facility houses over 75 metal stamping presses and the necessary support equipment. Our presses range in size from 50 tons to 1500 tons.

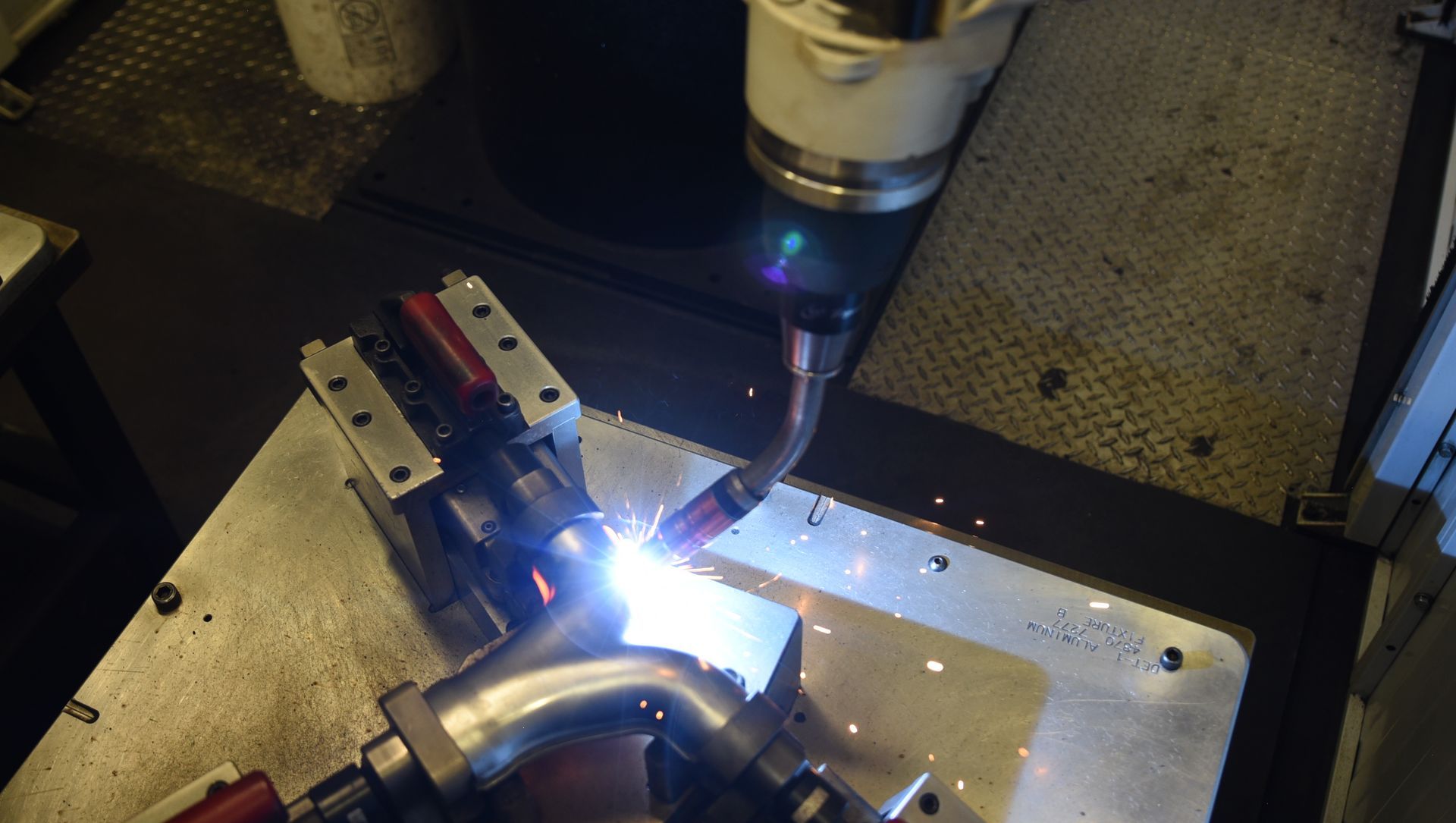

Welding

We have numerous robotic weld cells, each capable of handling multiple weld operations in a production environment.